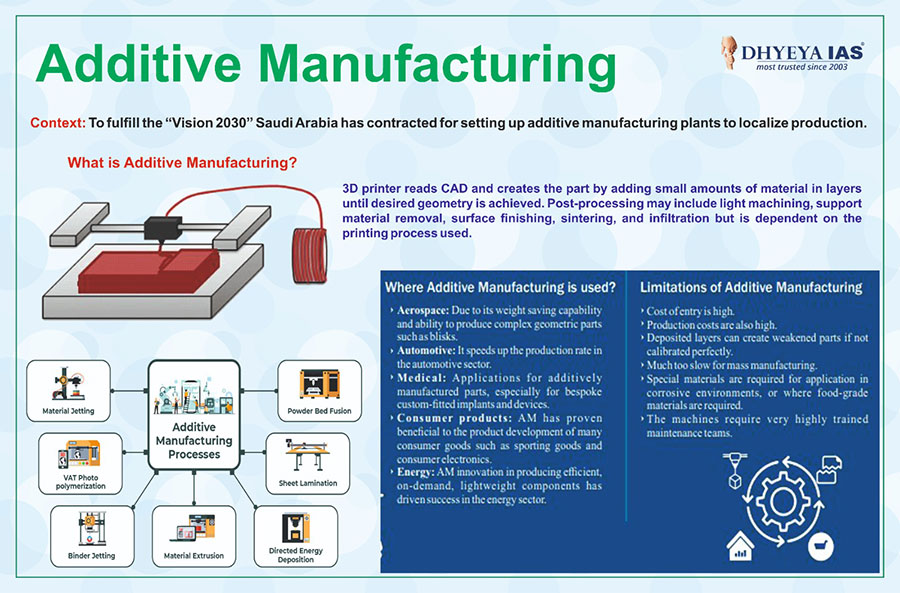

What is Additive Manufacturing?

3D printer reads CAD and creates the part by adding small amounts of material in layers until desired geometry is achieved. Post-processing may include light machining, support material removal, surface finishing, sintering, and infiltration but is dependent on the printing process used.

Additive Manufacturing Processes

- Material Jetting

- VAT Photo polymerization

- Powder Bed Fusion

- Sheet Lamination

- Binder Jetting

- Material Extrusion

- Directed Energy Deposition

Where Additive Manufacturing is used

- Aerospace: Due to its weight saving capability and ability to produce complex geometric parts such as blisks.

- Automotive: It speeds up the production rate in the automotive sector.

- Medical: Applications for additively manufactured parts, especially for bespoke custom-fitted implants and devices.

- Consumer products: AM has proven beneficial to the product development of many consumer goods such as sporting goods and consumer electronics.

- Energy: AM innovation in producing efficient, on-demand, lightweight components has driven success in the energy sector.

Limitations of Additive Manufacturing

- Cost of entry is high.

- Production costs are also high.

- Deposited layers can create weakened parts if not calibrated perfectly.

- Much too slow for mass manufacturing.

- Special materials are required for application in corrosive environments, or where food-grade materials are required.

- The machines require very highly trained maintenance teams.